Slide

Injector Skids

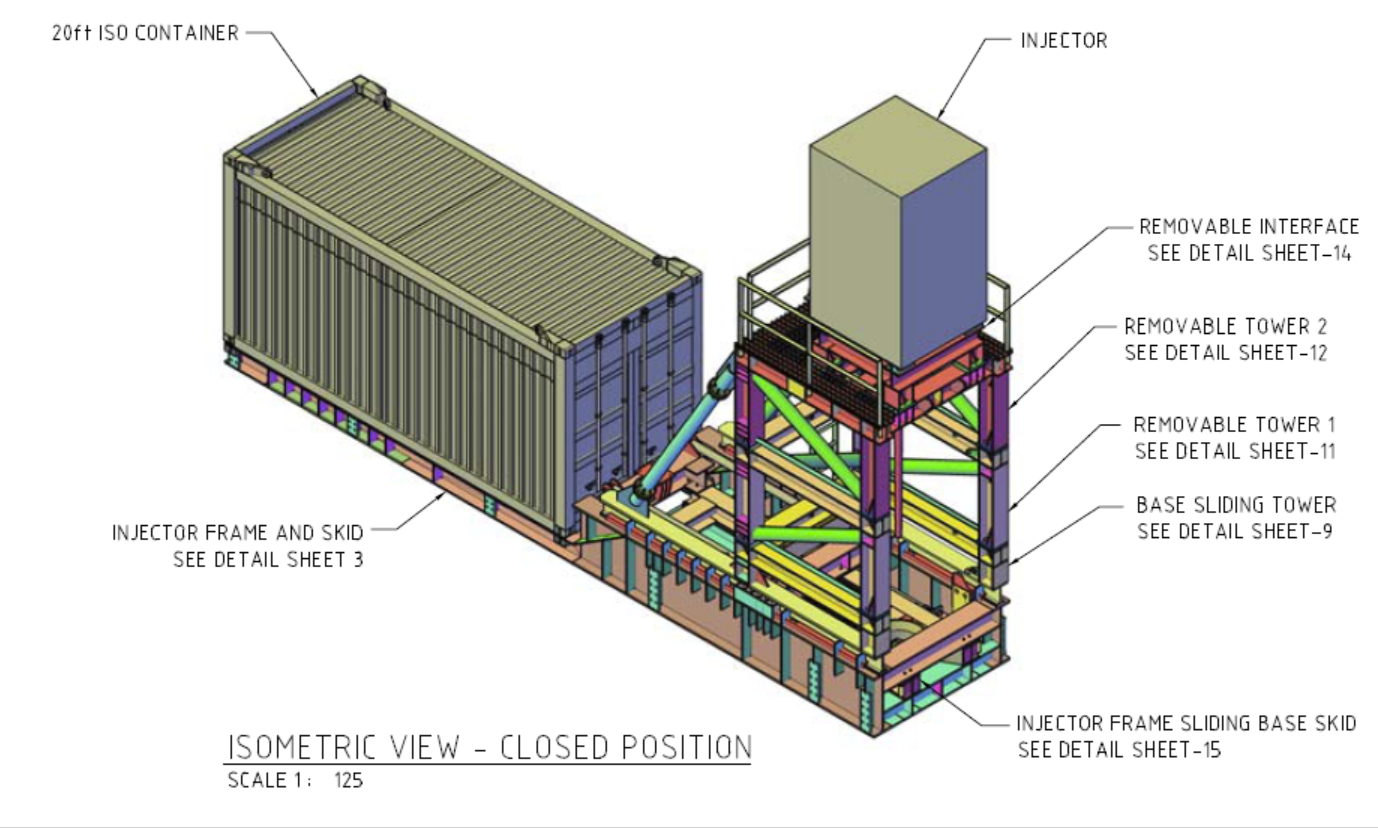

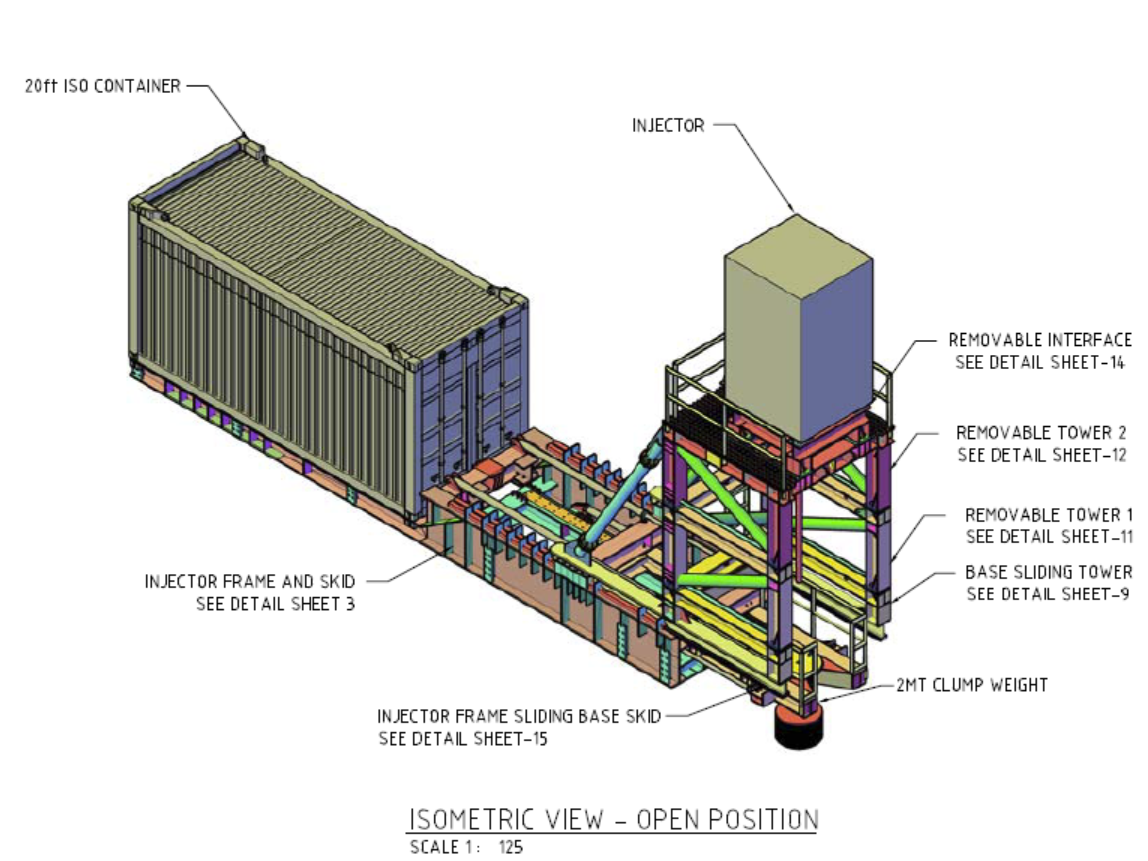

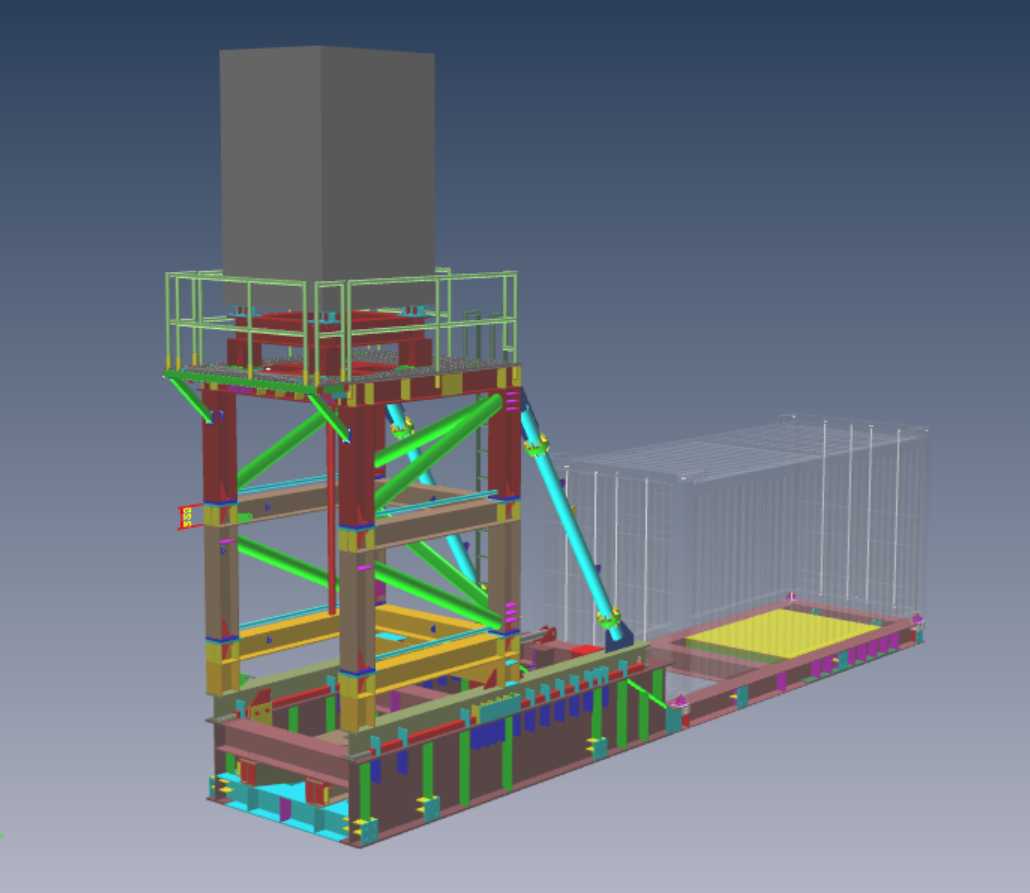

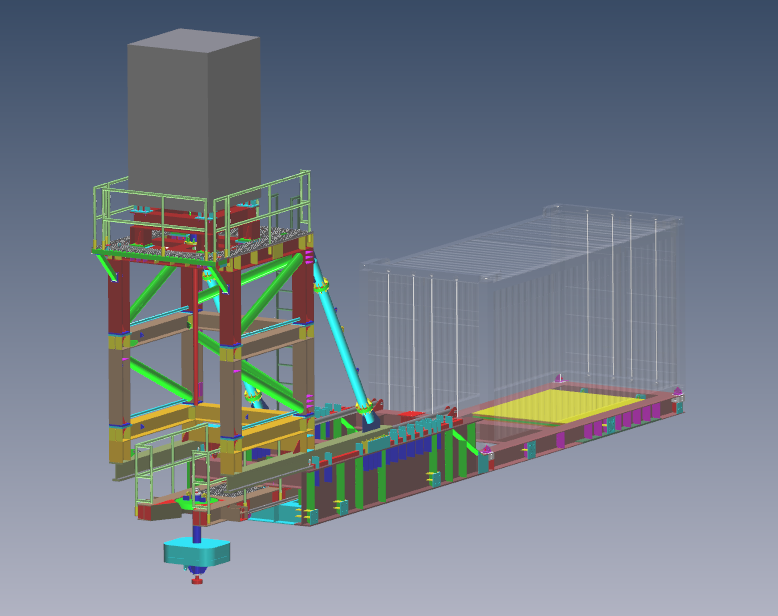

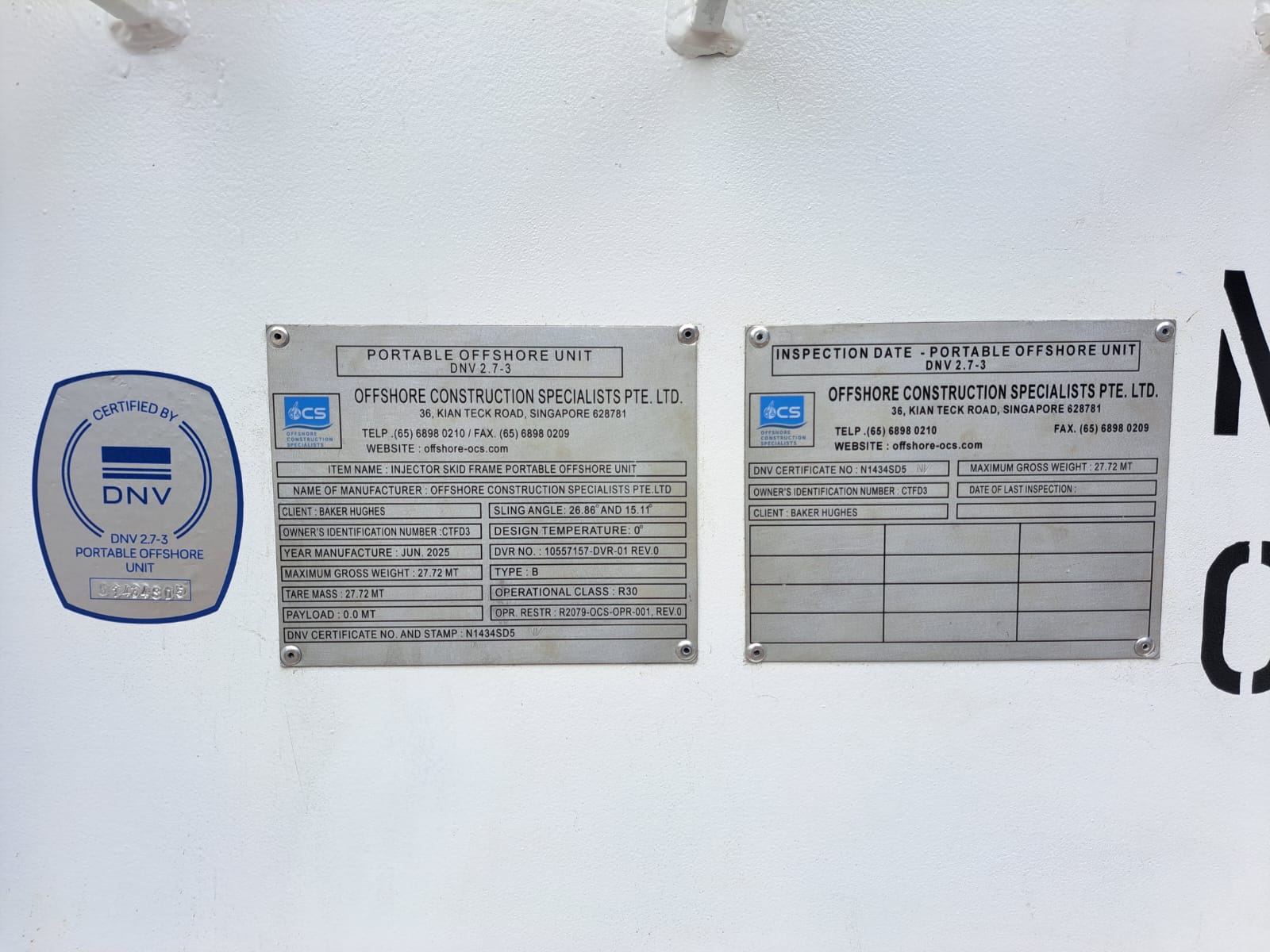

OCS was commissioned to design and fabricate two bespoke Injector Skid Frames for our client, Baker Hughes. These were specifically engineered to support critical coil tubing operations in offshore environments. Both injector frames were fully certified under DNV 2.7-3 standards which extensively covered design, fabrication and load testing, ensuring compliance and reliability for offshore use.

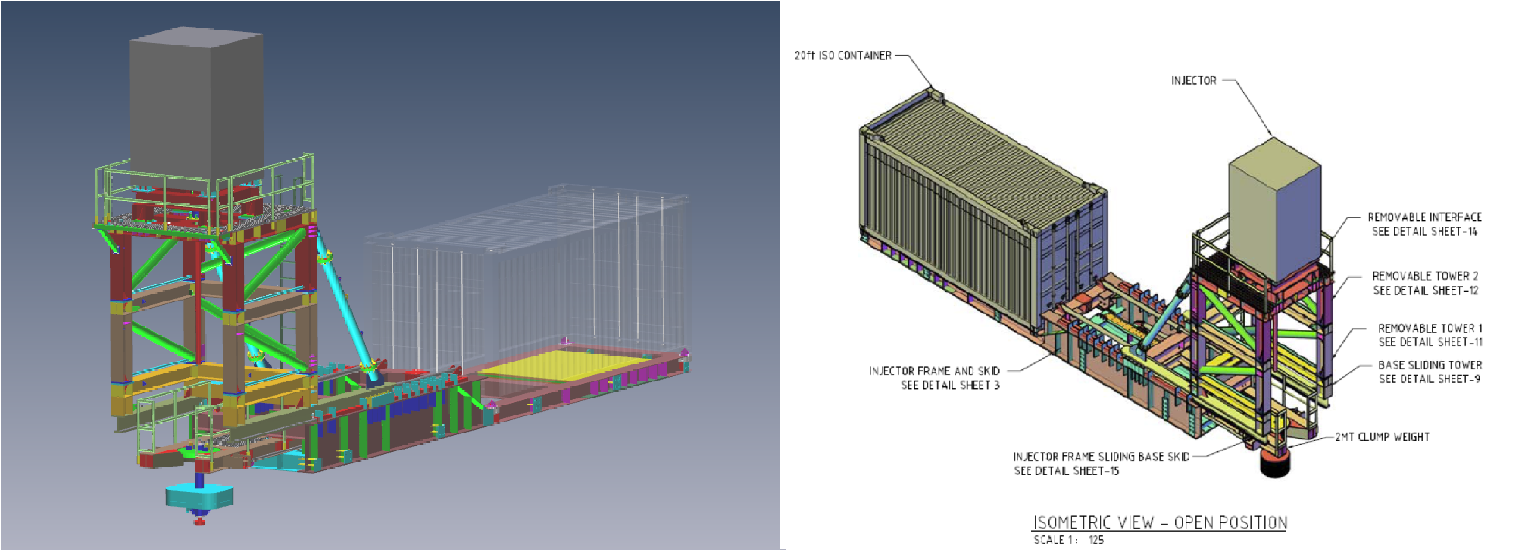

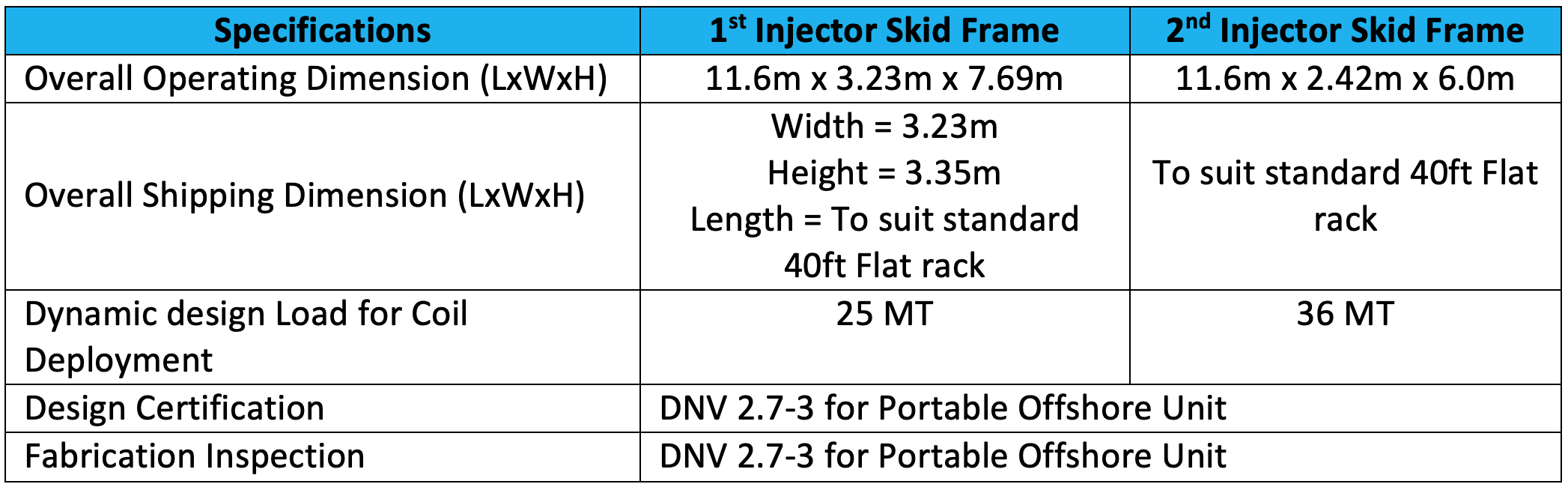

Each frame was engineered with two extended platforms that were designed to support the clump weight system and the main injector, allowing for smooth and safe coil tubing deployment. The first injector skid frame was designed for a 25MT dynamic load, while the second frame was engineered for a 36MT dynamic load.

With dimensions of up 11.6m x 3.23m x 7.69m, these frames were engineered to exacting standards while balancing strength, functionality and transportability.

Speaking of logistics, a key feature of these injector frames is their modular structure, optimized for transport and offshore handling. Both units were purpose-built to fit within the standard 40ft flat rack dimensions, for ease of logistics without compromising structural strength or safety. This design flexibility ensures that the equipment can be deployed efficiently across multiple offshore locations and projects.

From concept to completion, OCS delivered a full turnkey solution encompassing conceptual design, structural engineering, fabrication, assembly and DNV inspection/certification.

The successful delivery of these injector skid frames highlights OCS’s capability in providing bespoke, fully engineered equipment packages that support complex offshore operations. Whether for coil tubing deployment, subsea intervention or specialized lifting applications, our team ensures every piece of equipment is built with safety, durability, and client-specific requirements at the core.

For more information or to discuss custom-engineered solutions for your projects, please contact OCS.