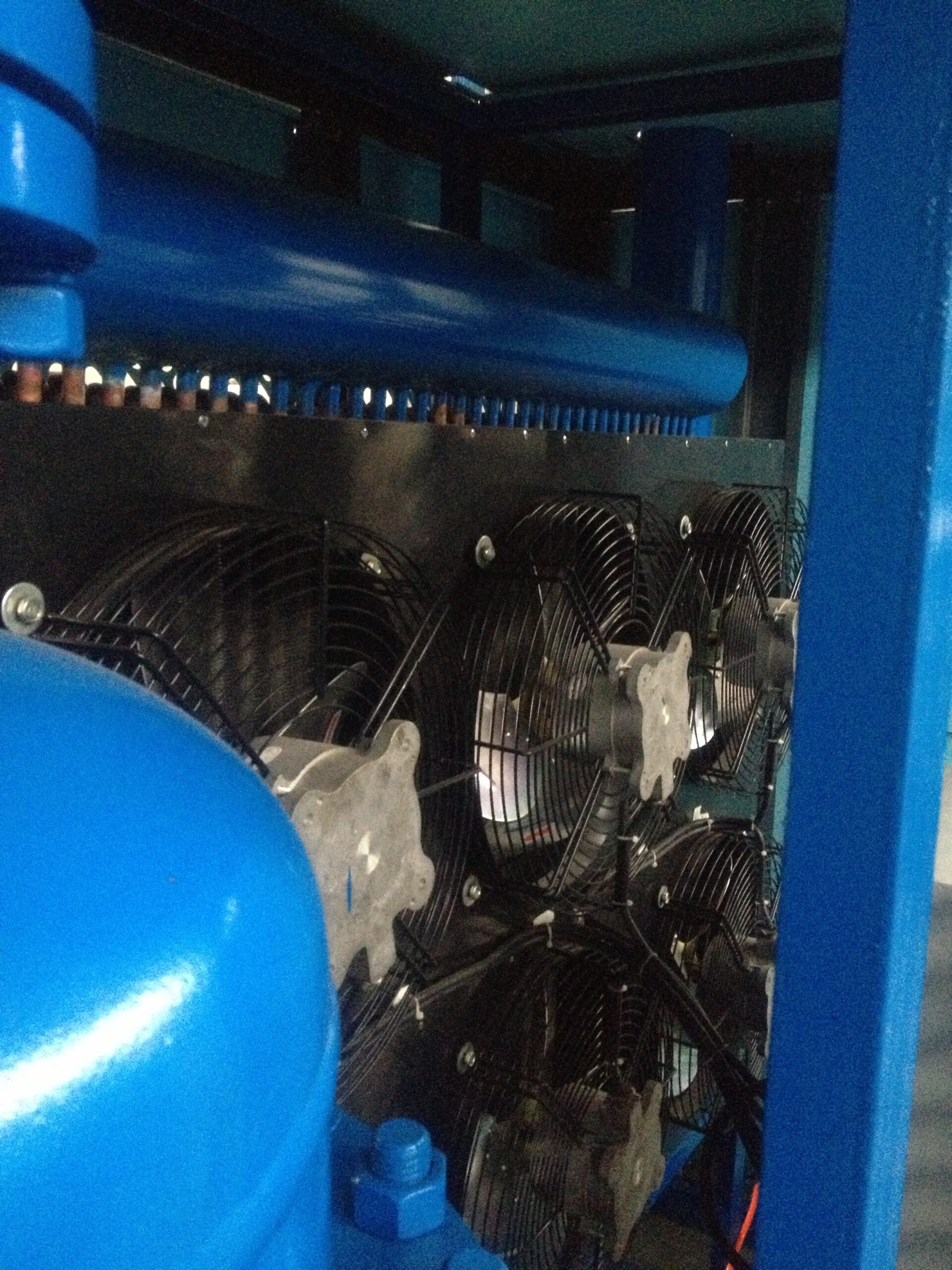

3000cfm After Cooler

Drying pipelines initially involves pigging with dry air. The dry air will absorb the water left from the dewatering phase. The process of running pigs and dry air through the pipeline is continued until the desired dew point at the outlet is met.

OCS has the expertise and equipment to perform this operation. OCS is equipped to handle large projects or discrete project elements depending on the specific needs of the customer. During the preparation for air drying or any offshore work, the safety of personnel, equipment and environment plays a vital role in the success of a project and as such, HAZID’s shall be conducted prior to any operations. These meetings are attended by key engineers and supervisors and all potential risks are identified and mitigation measures put in place to ensure they are as low as reasonably practicable.

OCS owned Air Drying spread is used in the pipeline pre commissioning operation spread for the drying operation. The drying of pipeline only applies for gas pipelines, to avoid formation of hydrate or corrosion. There are various methodologies for drying pipelines such as methanol, air drying vacuum and nitrogen. The most commonly used is dry air. The advantages of super dry air process are; low dew point, corrosion protection and economical, safe, non-hazardous cleaning action. The pipeline will be dried by the introduction of oil free and -70°C of super dry air.

The main air drying spread consists of the follow equipments;

- Heat Regenerative Air Dryer

- After Coolers

Support Equipment(optional)

- Oil Mist Filter

- Air Compressors

- High Temperature 2” Hoses

- 2” CLASS 300 Y Piece 4 way Manifold

- 100KVA Generator

- Air flow meter

- Portable Dew point meter

- Pipeline Pre-Commissioning