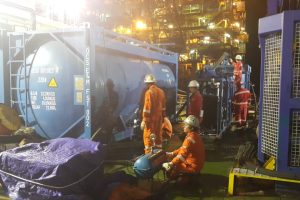

Pipeline free span correction equipment

Spans are corrected by placing grout bags underneath the pipeline and filling them with liquid cement or grout. Excessive Spans have to be corrected prior to pipeline pre-commissioning (flooding) so it is often advantageous to combine free span correction and pipeline pre-commissioning contracts. To achieve this, clients will need the equipments which OCS owns.

OCS owned complete free span correction equipments spread have proven successes for our existing clients time and time again.

OCS has the expertise, key personnel and equipment to provide single source, cost effective, trenching and burial for marine pipeline. OCS owns all the key elements of the pipeline free span correction equipment spread. The equipment can be mobilized at a relatively short notice onto an OCS barge or a 3rd party barge provided by the customer

The Free span correction equipment spread consists of the following equipments;

- Grout pump

- Silo tank

- Hopper tank

- Turntable

- Grouting spooler

GROUT PUMP SPECIFICATIONS | |||

Power Train | Detroit Diesel Series GM 4-71 N65 Injectors | Fluid End Pump Model | Magnum Centrifugal Pump 250X |

Engine Type | 2 Stroke | Impeller Diameter | 14” RH |

Number of Cylinders | 4 | Temperature Range | -20°C to +65°C

|

Power Output | 95BHP (71kw) @1200rpm | Pump Size | 5 x 6 x 14 |

Gross Power Output | 155 BHP (116kw) @ 2100rpm | Flow Rating | 20m³/hr |

Peak Torque | 407 lb ft(552N.M) @ 1600rpm | Pump Inlet | 4” WECO Fig 100 |

Compression Ratio | 18.7 : 1 | Pump Outlet | 3” Victaulic |

Skid Framing | 3000 x 1000 x 1800mm | ||

Weight | 2MT | ||

No of Units | 1 | ||

Hopper Tank Mixer Specifications | |

Mixing Capacity | 1.8m3 |

Pump Type | Magnum 6’ x 5” |

Engine Unit | Detroit 4-71 |

Pumping Capacity | 4m3 per hour |

Operation Type | Manual Controls |

Skid Frame | 1800 x 1400 x 2300 |

Number of units | 1 |

Turn Table Specifications | |

Outside Diameter | 2.4m |

Height | 2.0m |

Weight | 500kg |

No of Units | 1 |