Slide

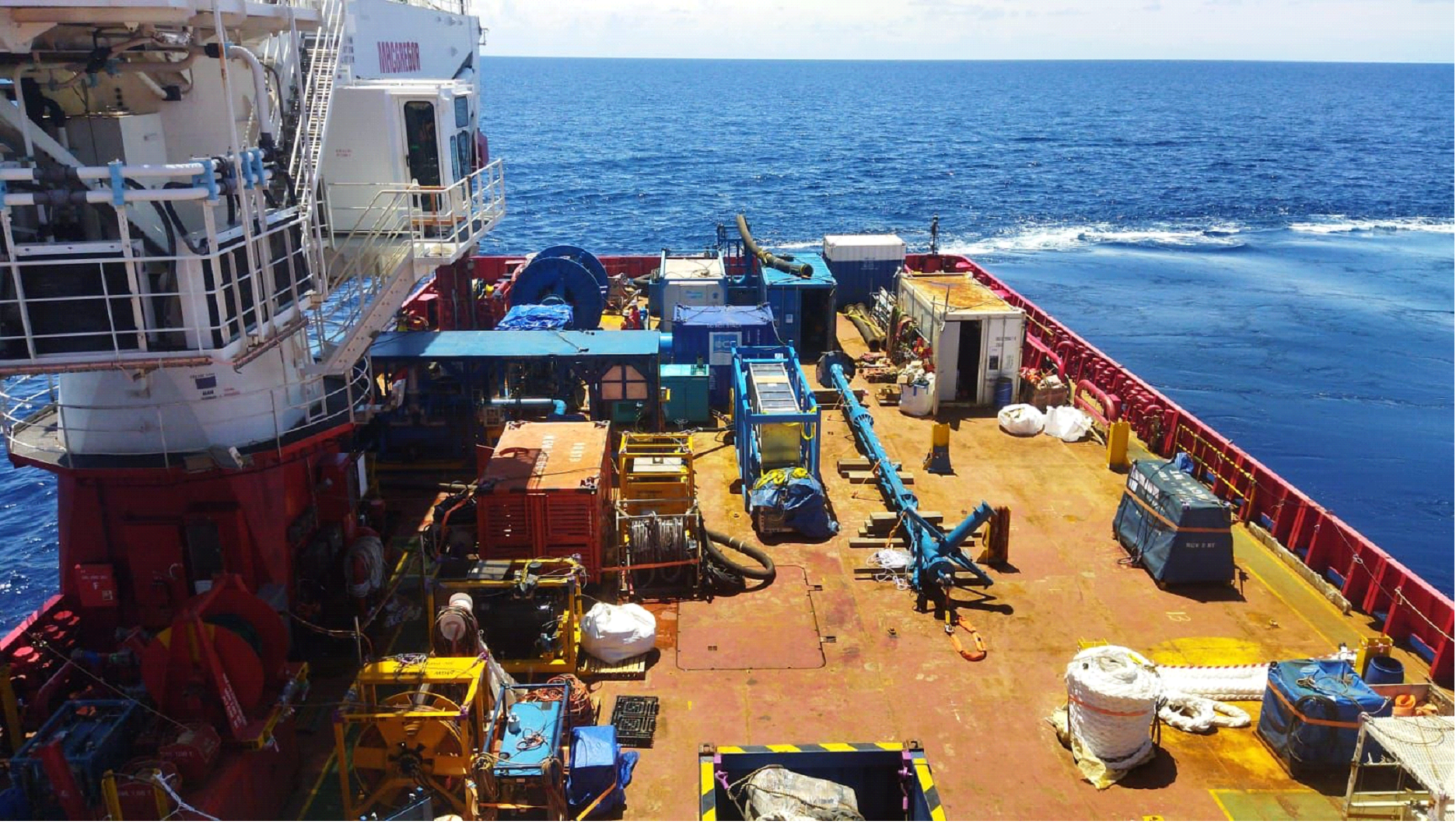

Internal high pressure water abrasive suspension cutter spread

OCS owns and operates a complete Internal High Pressure Water Abrasive Suspension Cutting System, purpose-built for internal cutting of piles, conductors, and jacket legs in offshore decommissioning and subsea construction scopes. The system is designed for precision, safety, and efficiency, even in challenging and hazardous environments.

The core components of the system include:

- High Pressure Pump (HPP) – supplies the necessary flow and pressure for cutting operations.

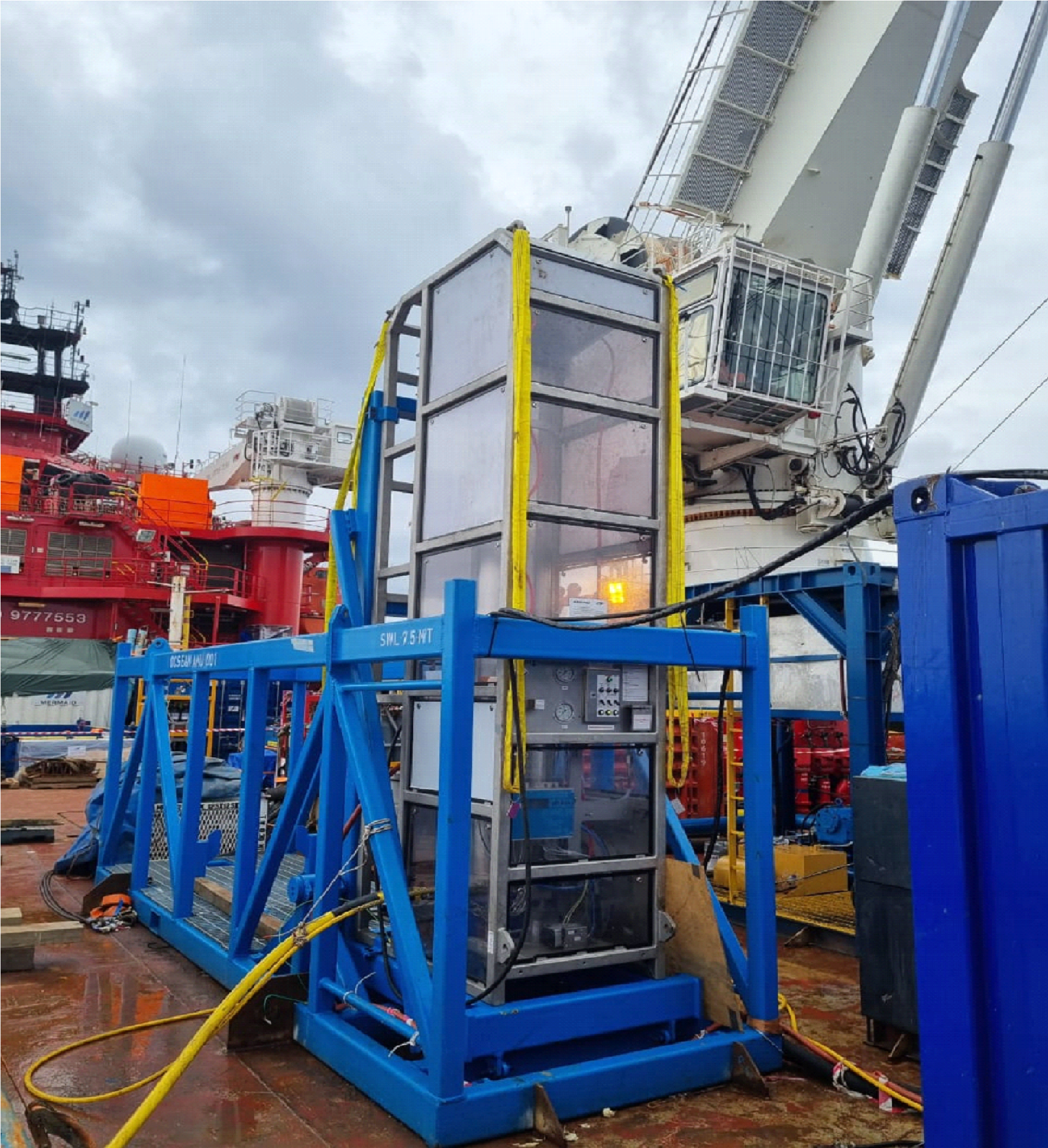

- Abrasive Mixing Unit (AMU) 2500-100MK2 (Self-Upend) – blends abrasive garnet into the water stream to create a high-energy Water Abrasive Suspension (WAS).

- Cutting Heads:

- DCH1 (Downhole Cutting Head 1): for pipe/pile diameters up to 20″

- DCH3 MK3 (Downhole Cutting Head 3): for pipe/pile diameters from 30″ to 72″

- PCH MK2 (Pile Cutting Head): for pipe/pile diameters from 16″ to 36″

- Control Cabin with 3S Cut Verification System – provides full remote operation and monitoring of cut quality and parameters.

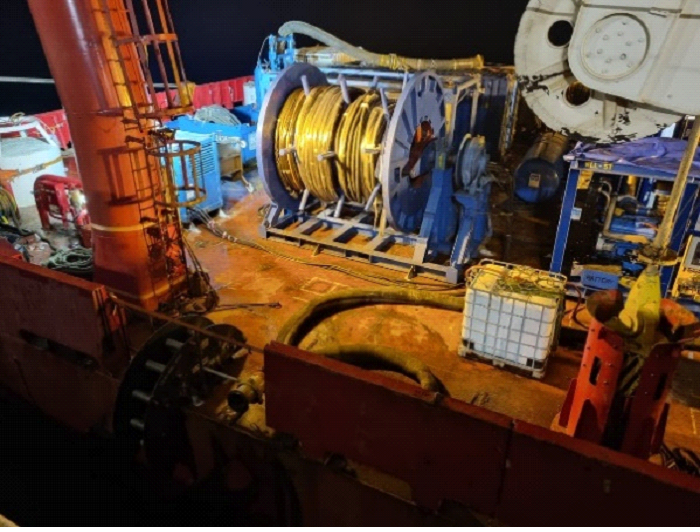

- Umbilical Spooler – manages deployment of the high-pressure lines and sensor cables.

In operation, high-pressure water is pumped into the AMU, where it is mixed with abrasive media to form the Water Abrasive Suspension. This suspension is then delivered to the cutting nozzle, where kinetic energy is focused to perform precise internal cuts. Known as a cold-cutting method, this process generates no significant heat or sparks, making it a safe and effective solution for cutting in hazardous or sensitive environments.

The integrated 3S Cut Verification System ensures real-time visibility and control of the cutting process, allowing operators to confirm the completion and quality of each cut, especially in complex multistring casings.

Internal High Pressure Water Abrasive Suspension Cutting Spread: Download