Marine And General Engineering

Engineering That Connects Design to Execution

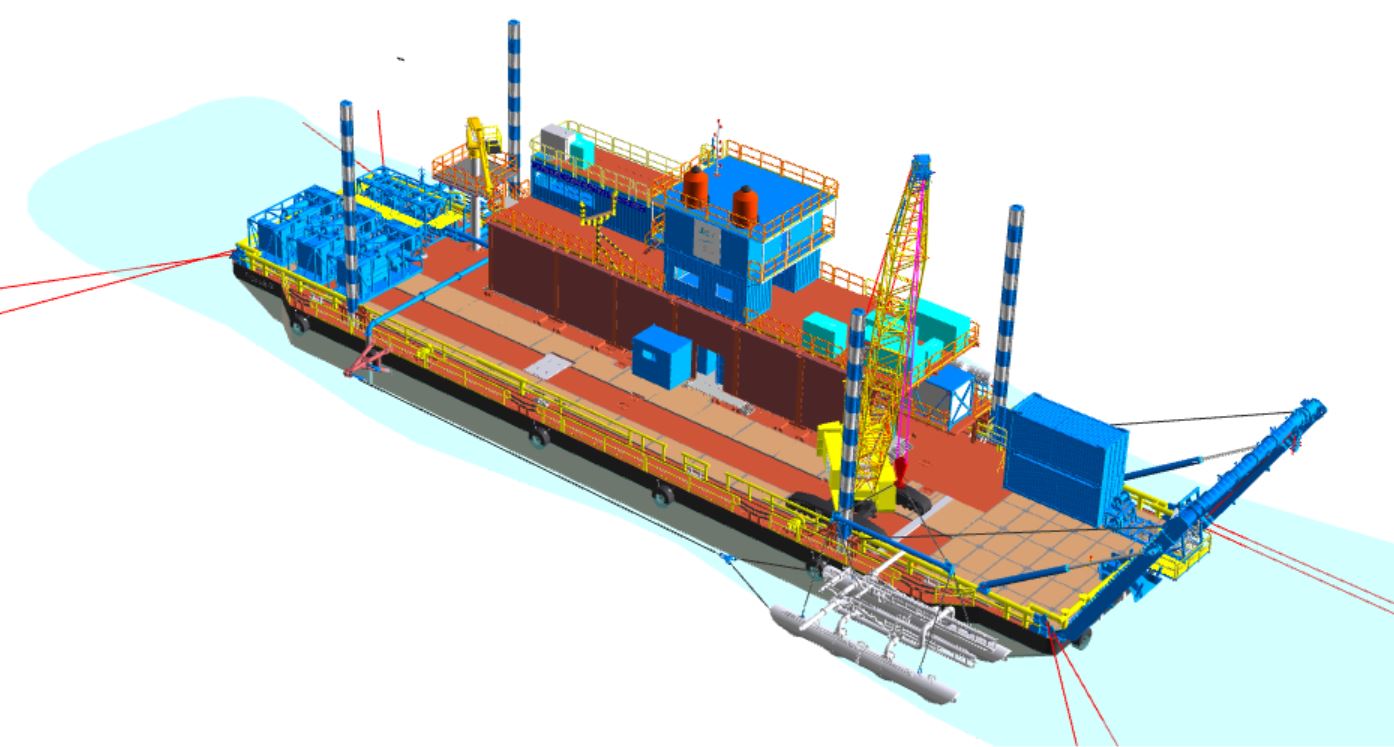

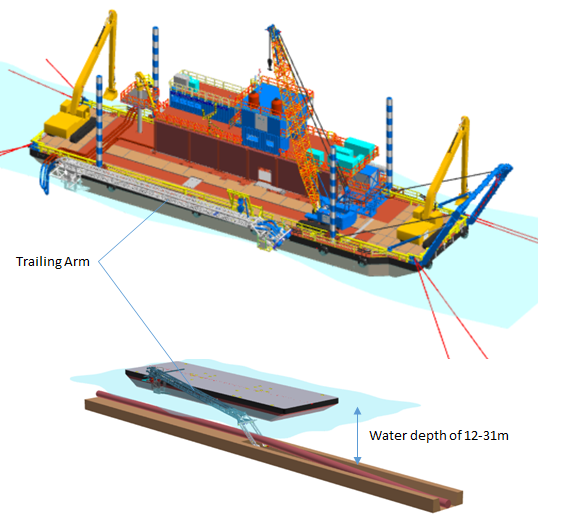

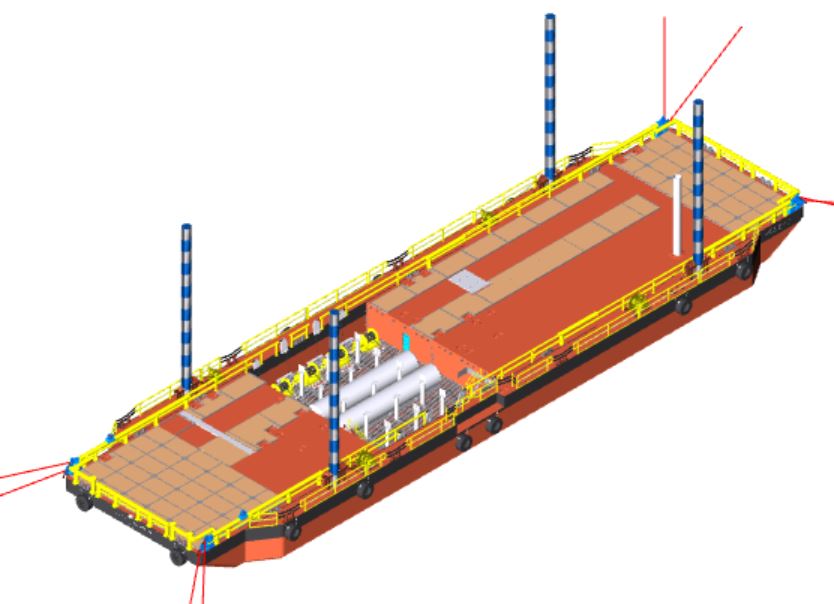

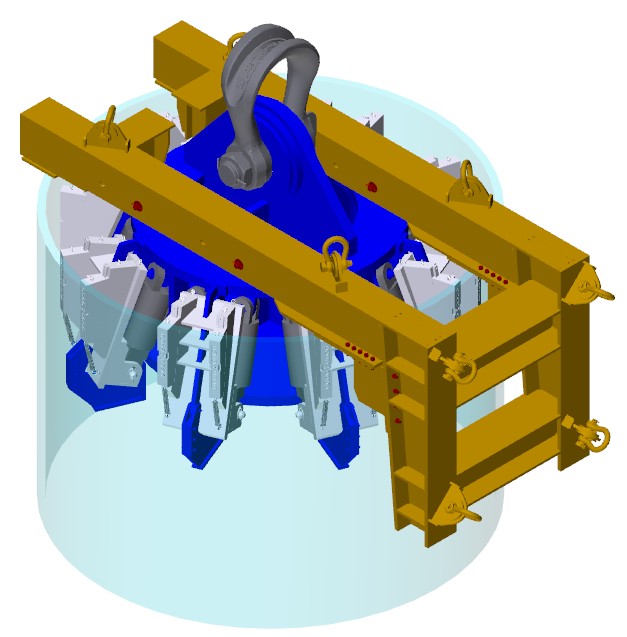

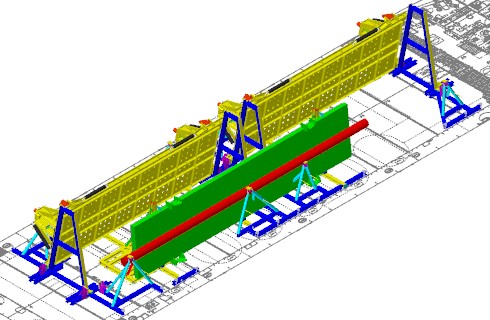

At Offshore Construction Specialists (OCS), our Marine and General Engineering group is the technical powerhouse behind the company’s ability to deliver fully integrated, constructible offshore solutions. From the design of complex marine structures and pipelines to detailed installation analysis for floatovers, trenching, moorings, and subsea installations, our engineers work across all technical disciplines to support projects from concept through execution.

What sets OCS apart is our fusion of deep technical knowledge with on-the-ground constructability. Our engineers interface directly with construction and equipment teams to ensure that every calculation, model and design package is aligned with offshore execution realities. This integrated approach reduces error, saves time, and delivers more efficient results for clients.

While our primary focus is the offshore oil and gas and renewable energy sectors, our team also supports general engineering challenges across a wide range of marine infrastructure projects. All engineering is class-compliant, field-tested, and delivered with clear documentation. Below is a comprehensive breakdown of our capabilities:

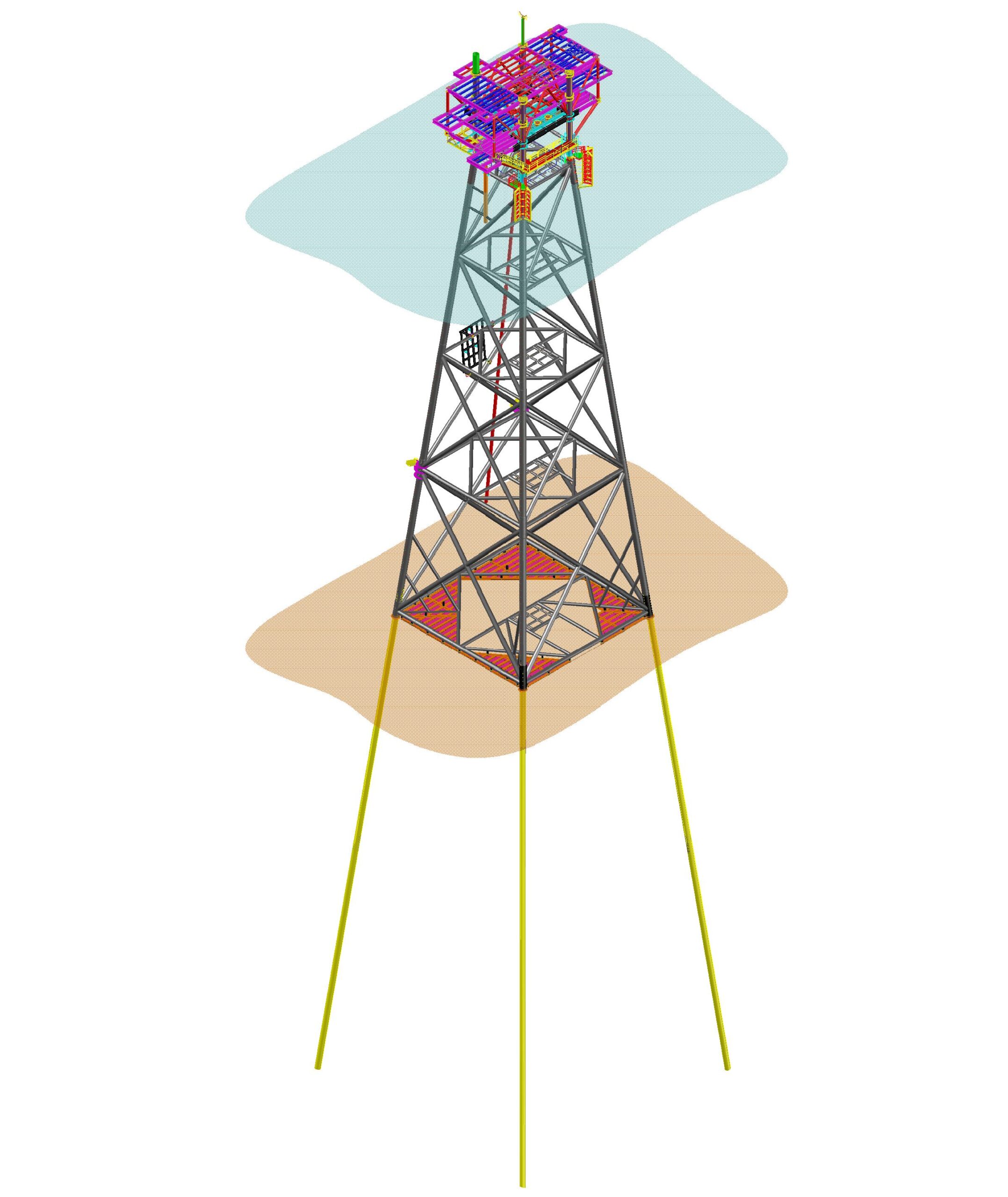

Structural (Jacket and Topside) Engineering

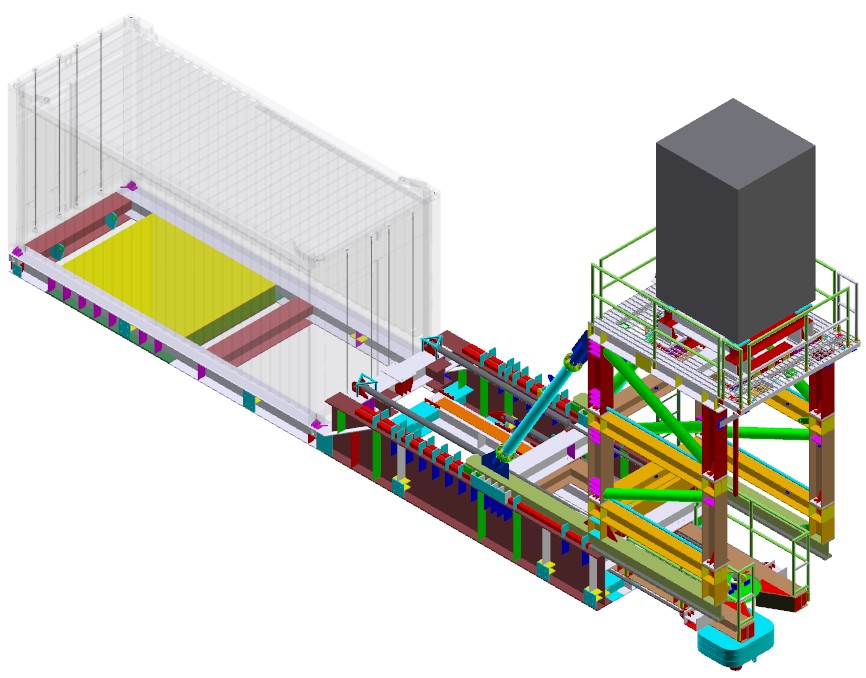

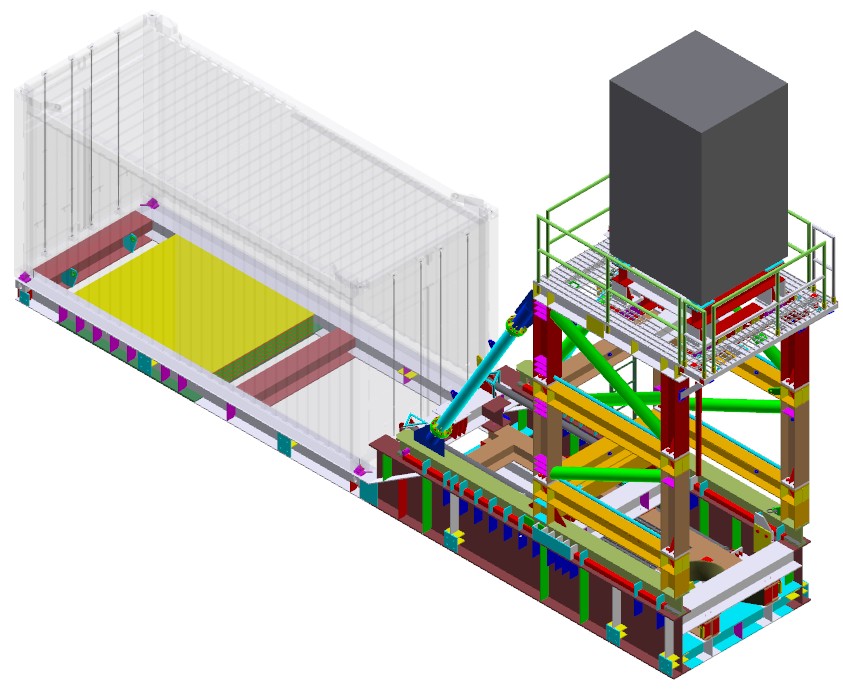

Process & Piping Engineering

- Equipment Sizing Studies

- Flare System Analysis (Dispersion and Radiation)

- Operating/Startup/Shutdown Philosophies

- P&ID Generation

- Piping Stress Analysis

- Piping Layouts and Isometrics

- Material Take-Off (MTO) and Specifications

- Software: HYSYS, CAESAR II, PDMS, AutoCAD, MathCAD

Electrical & Instrumentation Engineering

- Power System Studies and Load Lists

- Cable Sizing and Single Line Diagrams

- Earthing & Lighting Layouts

- Hazardous Area Classification

- E&I Specifications and MTOs

- Hook-up Drawings and Cable Schedules

- Instrument Loop, I/O List and F&G Schedule

- Cause & Effect Drawings and Data Sheets

- Software: ETAP, AutoCAD, MathCAD

FPSO and Floating Unit Design & Mooring Installation

- Structural and Mechanical Design for Modules

- Electrical, Piping and Process Design for FPUs

- FPSO/FSO Station Keeping Analysis (incl. Tugs, Mooring Tensions)

- Chain Mooring Installation and Catenary Analysis

- Force Calculations on Mooring Towers

- Software: MOSES, Orcaflex, MathCAD

Pipeline Design & Installation Engineering

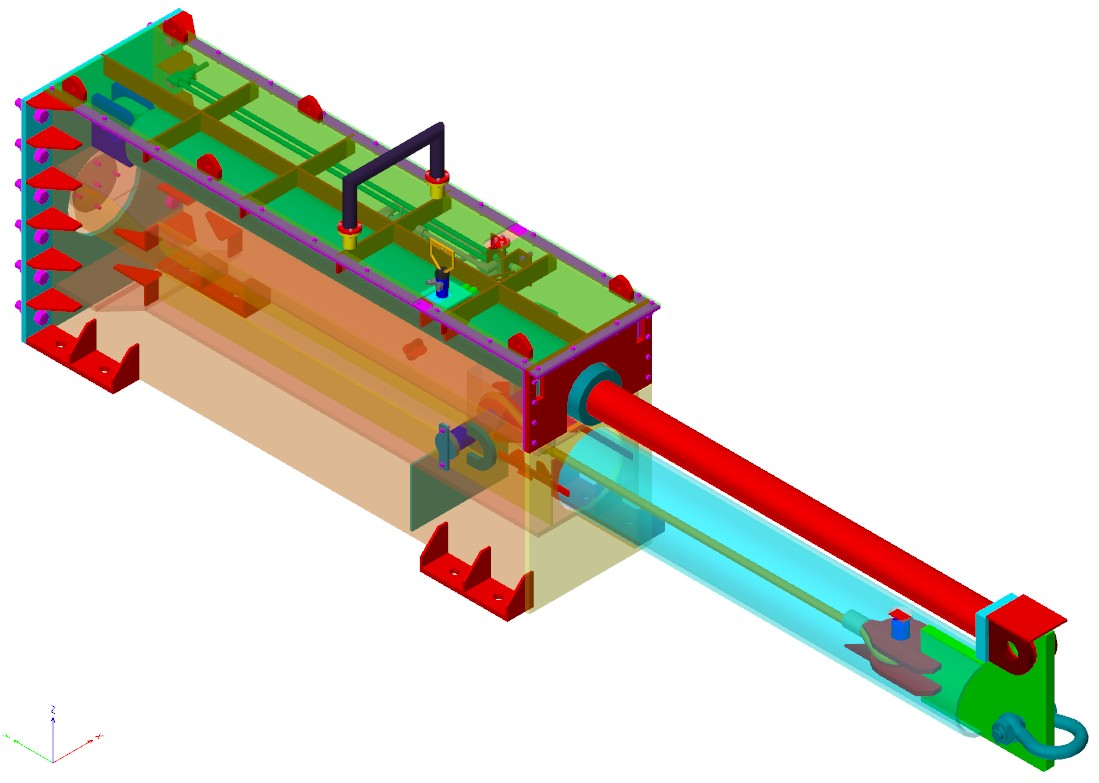

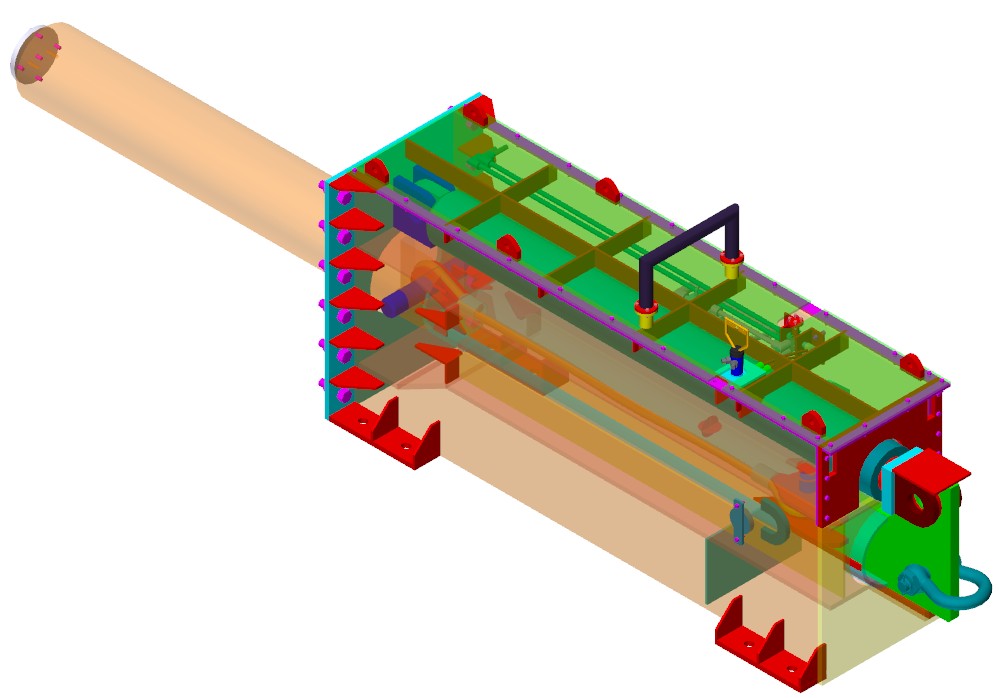

SURF Installation & Cable/Umbilical Engineering

- J-Tube Pull Force Analysis for Cable Start-Up

- Static & Dynamic Lay Profile Analysis

- Inline Connector and Laydown Studies

- Fatigue and Catenary Analysis for Flexible Hoses

- Downline Pre/Post Connection Top Tension & End Force Analysis

- Software: Orcaflex, MathCAD

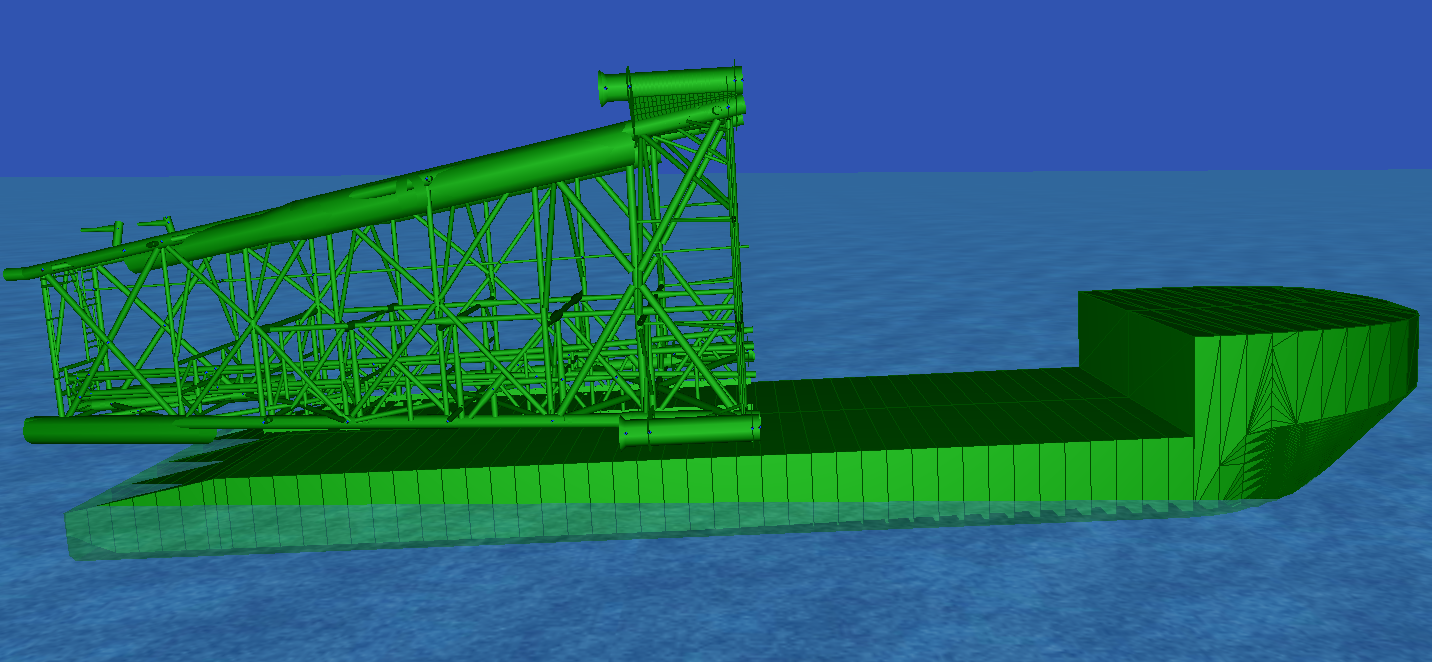

Naval Architecture & Float-over Studies

- Tow & Stability Analysis

- Bollard Pull Calculation & Engineered Lift Studies (DAF)

- Mooring Analysis: Pattern, Tension & Vessel Excursion

- Jacket Floatation, Launch and Upend Studies (Dive Depth, Clearance, Stick-Up, Flooding, Sling Loads)

- Float-over Mating Load Analysis (LMU, DSF, Fender Loads)

- Software: MOSES, Orcaflex, MathCAD

Geotechnical Engineering

- Pile Drivability Studies

- Hammer Adequacy & Dynamic Stress Checks

- Pile Section Optimization

- Slope Stability and Sheet Pile Design

- Software: GRLWEAP, MathCAD

Want engineering that delivers onshore and offshore?

Contact OCS today and speak with a team that knows how to engineer for execution.