Modec Mv12 Riser Remedial Project

Introduction

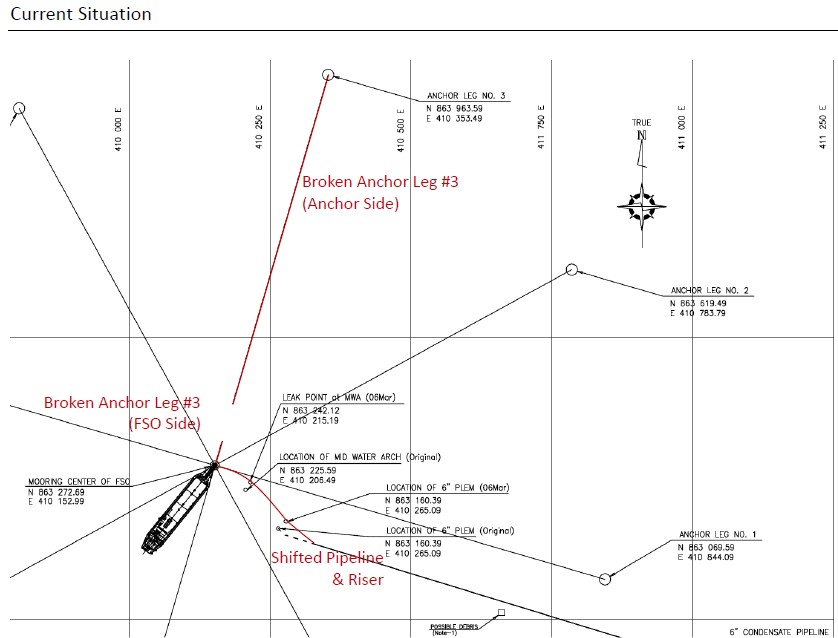

In late 2019, MV12 experienced a mooring failure when the mooring leg #3 load chain failed. An AHTS was dispatched to site to assist to hold the FSO against inclement weather. During the hooking up of the tow line, the tug’s towline allegedly hooked onto the MWA and PLEM, dragged and moved both the MWA and PLEM spool approximately 20m away from its original position. The MWA is currently in close proximity of the Mooring Leg #1. The PLEM spool has also been disconnected from the PLEM support clamp on PLEM base, which is still in its original position. A subsequent ROV inspection survey has indicated damage to the 6” Riser and to the PLEM tie-in spool/Flange connection where leaks have been observed. The 6” Riser cannot be used in its current damaged state with the consequence that the condensate cannot be loaded to the FSO which in turn affects the gas production of wellhead platform. A permanent long term repair of the mooring and riser is planned but can only be done in the next 6 to 18 months due to material availability. In the interim period a temporary repair is planned to enable the wellhead platform to continue production and product loading to the FSO.

In late 2019, MV12 experienced a mooring failure when the mooring leg #3 load chain failed. An AHTS was dispatched to site to assist to hold the FSO against inclement weather. During the hooking up of the tow line, the tug’s towline allegedly hooked onto the MWA and PLEM, dragged and moved both the MWA and PLEM spool approximately 20m away from its original position. The MWA is currently in close proximity of the Mooring Leg #1. The PLEM spool has also been disconnected from the PLEM support clamp on PLEM base, which is still in its original position. A subsequent ROV inspection survey has indicated damage to the 6” Riser and to the PLEM tie-in spool/Flange connection where leaks have been observed. The 6” Riser cannot be used in its current damaged state with the consequence that the condensate cannot be loaded to the FSO which in turn affects the gas production of wellhead platform. A permanent long term repair of the mooring and riser is planned but can only be done in the next 6 to 18 months due to material availability. In the interim period a temporary repair is planned to enable the wellhead platform to continue production and product loading to the FSO.

Solution

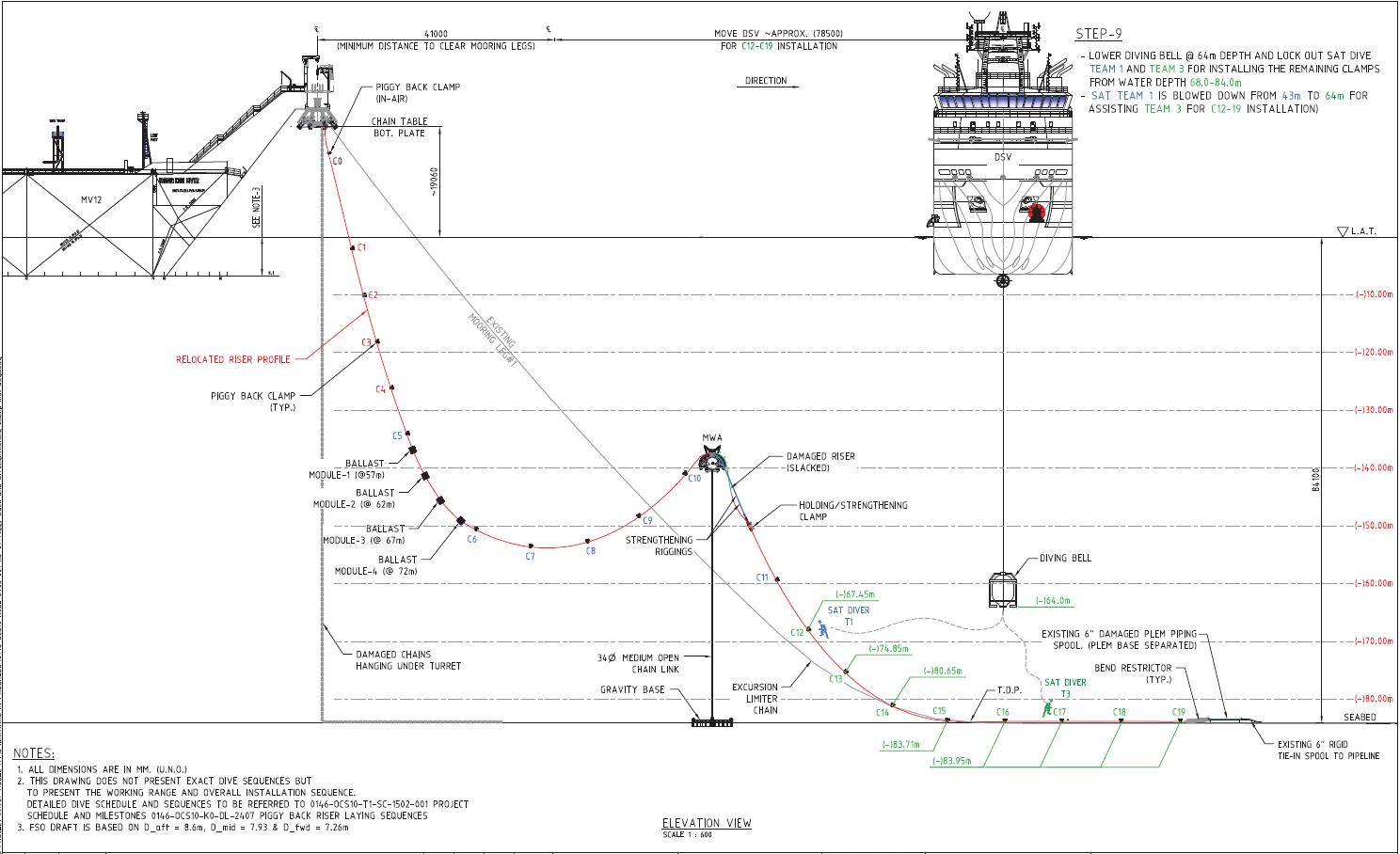

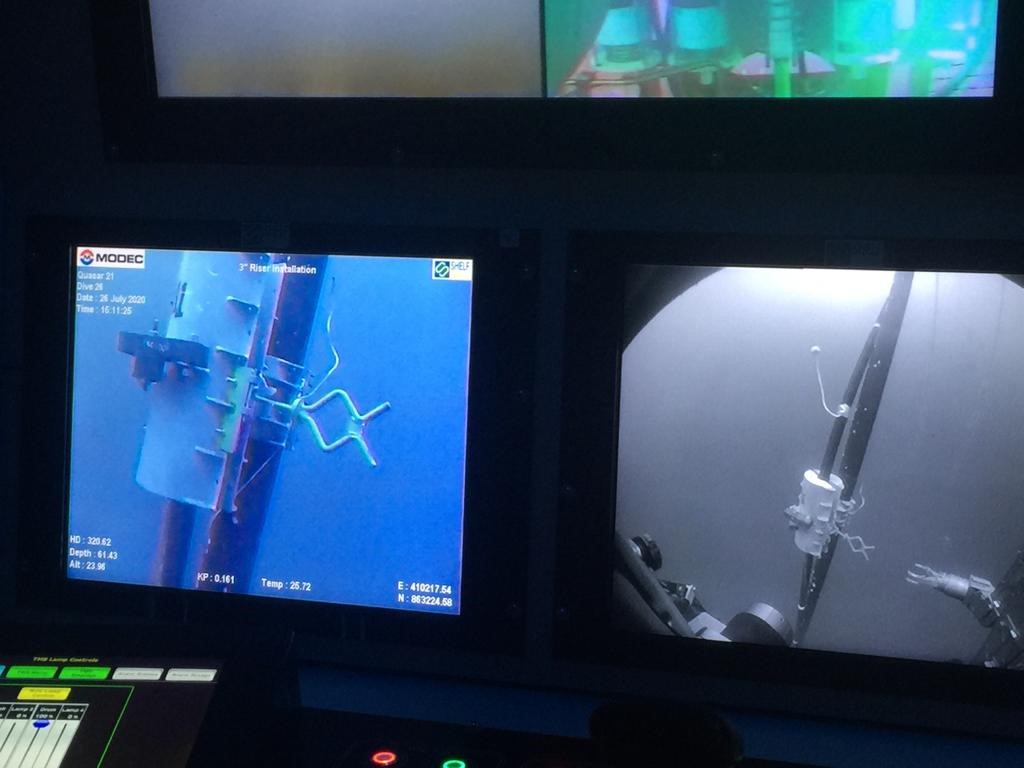

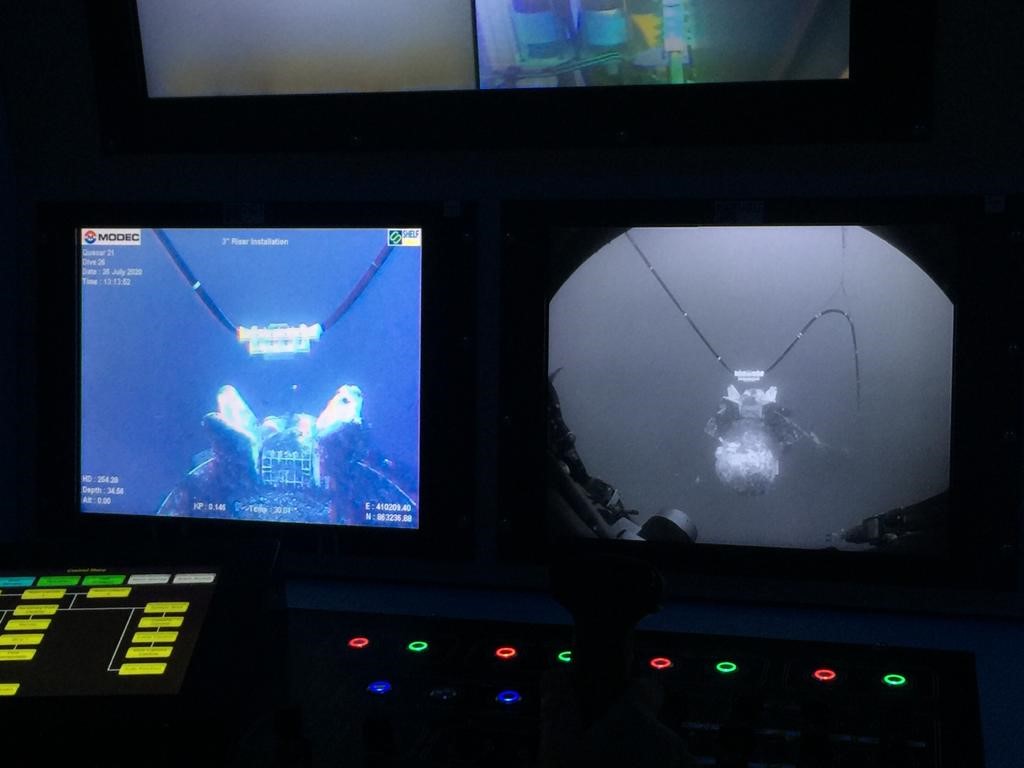

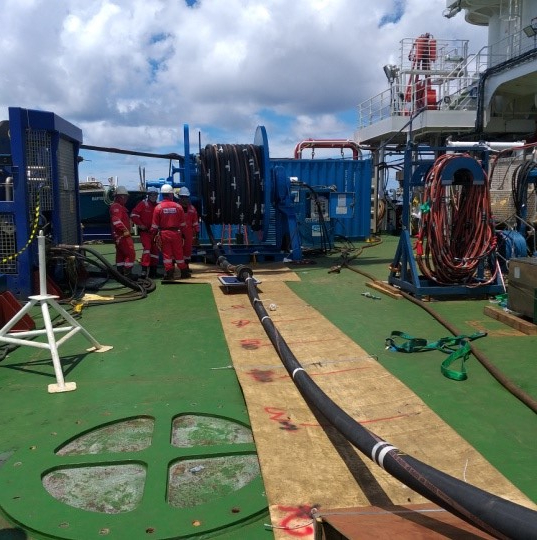

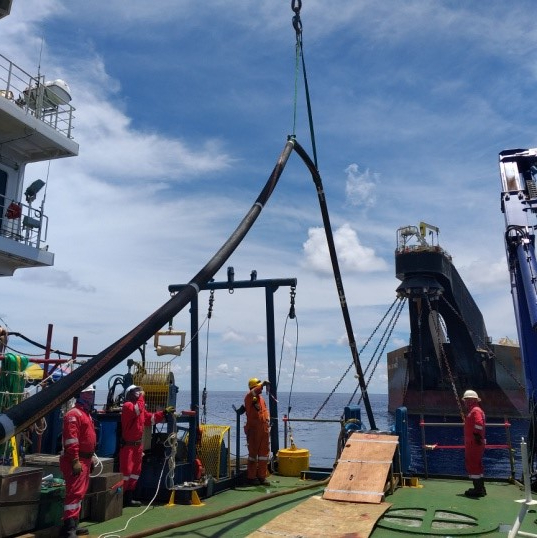

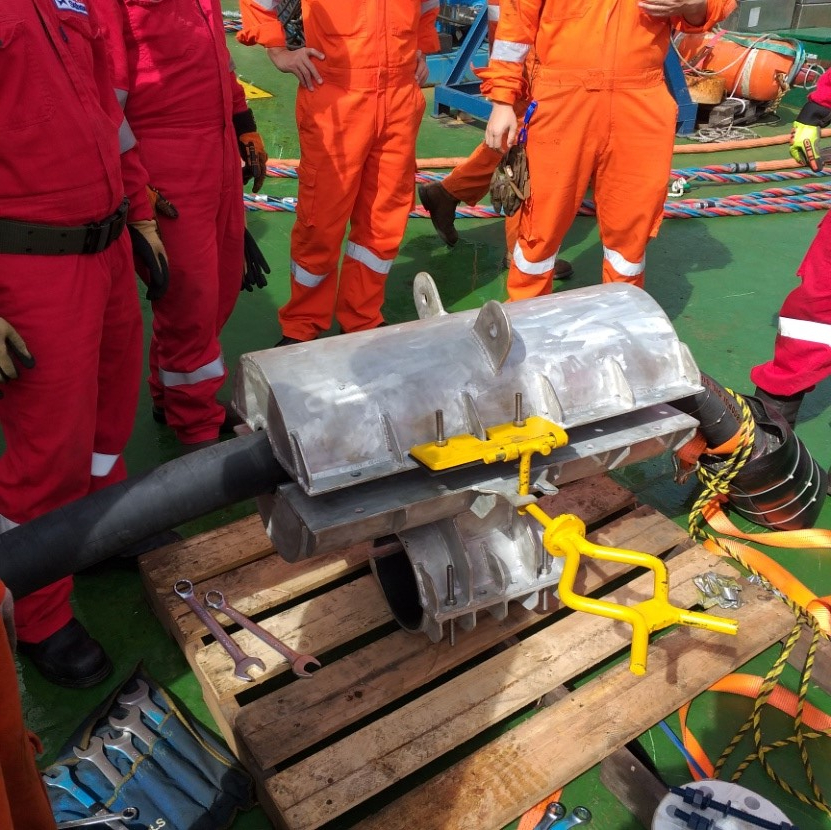

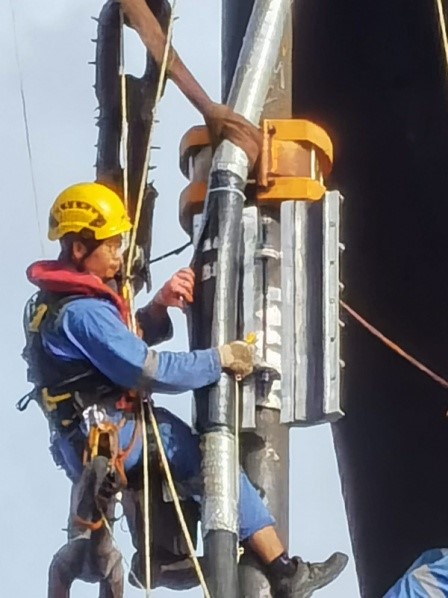

MODEC engaged OCS to provide a solution where OCS proposes to retrofit a 3” piggy back (by pass) hose attached to the existing damaged riser to enable the platform to resume production while waiting for implementation of a permanent solution. The operating period for the temporary system is expected to be around 6 months with a maximum design life of 18 months. Temporary reinforcement were made to the damaged riser. The temporary repair solution proposed minimizes requirement for extensive engineering and long lead procurement items. All required components proposed were available locally in Singapore and all engineering was performed at the OCS office in Singapore. OCS selected full aluminum construction of the piggy back clamps in view of the short duration use as well as weight consideration in order to ease handling and fabrication. Fabrication, assembly and testing of the aluminum clamps took place in the OCS fabrication facility in Batam. The design were endorsed by LOC.

OCS completed this challenging project in a relatively short period, in view of the impact of the COVID 19 pandemic occurred during that period. The project was awarded in April 2020. Engineering, procurement and fabrication of the aluminum piggy back clamps, steel riser strengthening clamps, steel 3” friction clamp to MWA, 3” replacement hoses (including spare) and all ancillaries were completed in early July 2020 and loaded out onto DSV Southern Star, chartered by MODEC.

OCS also provided Construction Management onboard DSV Southern Star for the offshore execution which was completed in early August 2020. OCS construction management team also prepared and conducted HAZID workshop for the work scope.