MODEC MV17 MOORING LEG REPLACEMENT PROJECT

Introduction

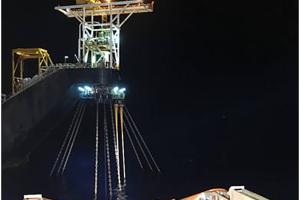

The FSO Rang Dong MV17 is owned and operated by MODEC Management Services (MMS) at Rang Dong Field which owned by Japan Vietnam Petroleum Company Limited (JVPC). FSO MV17 is installed in Rang Dong field located offshore Vietnam, approximately 135 km southeast of Vung Tau and started the its operation on 1st November of 2008. In December 2016, parties agreed to extend the charter contract to 2025 with 3-year further extension options. The original design life of the existing mooring and riser system is 10 years, therefore replacement of whole mooring legs and risers are required as a base case for life extension.

The FSO MV17 is located at Latitude 10°01.12’N, Longitude 108°16.08’E and approximately 2.5km from Wellhead platform. The FSO is moored at field with the external turret mooring system that consists of nine (9) anchor legs arranged in 3 x 3 groups, with drape chain and connected to drag anchor in the seabed in 56m water depth. FSO Production connected to WHP by subsea pipeline including crude oil and gas line.

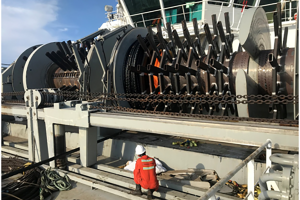

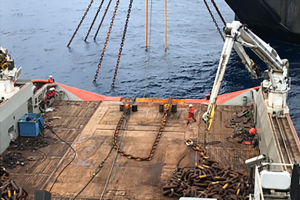

The new mooring system is a 3×3 configuration and consist of nine (09) 1067mm Ø x 27m anchor piles, nine (09) pile chain 89mm Ø x 115m long, nine (09) 89mm Ø x 702m ground wire, nine (09) 89mm Ø x 200m ground chain, nine (09) x double 152mm Ø x 80 weight chain and nine (09) 95.25mmØx61m top chain.

MODEC contracted PTSC Offshore Services (POS) for the replacement of the mooring. POS subcontracted the installation/construction engineering and construction management to OCS. OCS performed all transportation and installation engineering including Pile Drivability Analysis, pile and hammer handling, designing all installation aids including chase pile and chaser frame design, portable/removable wire reel partitions to store the mooring ground wires (avoiding the need to load the individual mooring wire reels) and developed all the installation procedures covering mooring pile installation, chain deployment, tensioning and chain hook up of new mooring system and the disconnection and recovery of the existing mooring system. OCS construction management team also prepared and conducted HAZID workshop for the work scope

OCS construction management included an offshore team onboard the construction barge POS01 and chain handling and tensioning vessel Pacific Diligence to supervise and support the installation and disconnection work. All offshore replacement work was performed while the FSO is still in operation mode and was completed in April 2018.