Pipe Lay Systems on PL1

POE-PL1 is a pipe lay barge with a fixed truss stinger. The same was modified and strengthened to be used for the Serica project to lay the 14” pipeline at a maximum depth of 55m. The modifications carried out were :

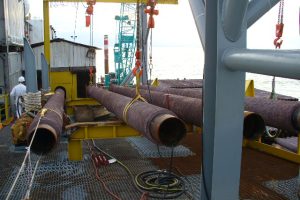

Stinger and A Frame strengthening: the stinger was a 2D plane truss which was not sufficient and user friendly for the purpose. Therefore a 3D truss stinger was conceptualized, designed and fabricated. The A-Frame support of the stinger was also re designed and strengthened to suit the excess load. A unique method to change the stinger angle using the fixed length pennants but different attachment points on the hook on the A Frame was conceptualized, designed and fabricated, this proved extremely efficient offshore since changing the stinger angle took very less time. The photos of the modified stinger and A-Frame and the hook connection are given.

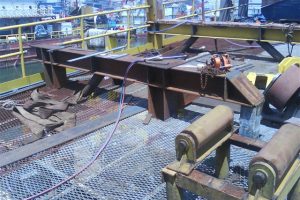

Ready rack and monorails: The barge did not have a ready rack and the loading onto the pipe ramp rollers was done by the crawler crane which was very weather sensitive. A ready rack was designed and fabricated such that five pipes could be stored at the pipe roller elevation and could be loaded onto the rollers. A unique way of loading on to the pipe rollers by using a monorail was conceptualized, design and fabricated. This proved extremely efficient offshore since it was very less weather dependent and the speed of loading the pipe onto the rollers was very high there by reducing the actual time required to lay each joint.

Stinger hitch: The stinger hitch on the barge was re designed and strengthened. An offshore friendly catcher arrangement was fabricated at the hitch location as a contingency in case the stinger has to be taken out and re instated offshore.

Modification Analysis Report was issued covering :

- Brief description of the work carried out

1. Strengthening of ready rack

2. Strengthening of monorails

3. Strengthening of pipe ramp supports below ready rack

4. Strengthening of the stinger and A Frame (includes checking of pennants) - Loadings

- The stresses / stress ratios in the members

- Photographs of the strengthening performed

- STAAD input/ output of all the structural analysis.