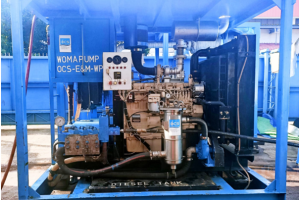

Woma Pump

| WOMA Pump | Quantity:1 |

|---|---|

| Maximum Operating Pressure[psi (bar)] | 7250 (500) |

| Maximum Volumetric Flow Rate ltr/min (USgpm) | 180 (47.5) @ 504 rpm |

| Details of Engine:- | |

| Manufacturer | Johndeere |

| Model | Powertech 8.1L 6081 OEM Diesel Engine |

| Drive | 160kW 6 Cylinder; 1800rpm radiator water-cooled |

| Transmission | Flexible Coupling |

| Stroke | 95mm (3.74ins) |

| Crankshaft | 504rpm via inbuilt reduction gear ratio of 3.57 |

| Details of Pump:- | |

| Pump | Manufacturer – WOMA Apparatebau GmbH |

| Model | WOMA 2502 P40 |

OCS owned Woma pump is skid mounted pumping unit, which is used for hydro static testing of subsea pipelines. Woma pump is a high pressure pump with a maximum operating pressure of 7000psi (500bar). This pump is a normally used for hydrostatic testing of long and larger diameter pipelines where high volumetric flow rate is required.

The power train used for this pump skids is a Johndeere Powertech 8.1L 6081 OEM diesel engine. This engine is a 4 cycle engine with in-line application. It has 6 cylinder engine with 8.1L (494 cubic inches) displacement producing 100BHP (75kW) @1000 RPM and upto 225 BHP (168kW)@2200RPM. In order to prevent overstressing the engine is usually run at approximately 1600RPM. The fuel consumption rate varies from 6 USG/hr @1000 RPM to 19.2 USG/hr @ 2200 RPM

The fluid end used in this pumping unit is WOMA 2502 P40 pump. This pump is positive displacement pump with a maximum volumetric flow rate of 130 lit/min @ 504rpm. This pump is also ideal for cleaning pipes, tube bundles, sewer lines, tanks and containers. The modular design provides a high degree of flexibility and allows varying the output parameters by a simple exchange of the interchangeable plunger sets. The pumps are equipped with an auxiliary shaft which allows coupling of a second pump thus doubling the output. A special feature of this pump is that it can operate with inlet temperature up to 65°C with possibilities to accept up to 90°C.

The pumps skids (2600 x 1600 x 2200mm x 3.5MT) have been designed to comply with DNV criteria (DNV 2.7-3) for offshore portable equipment lifting operations. The skid status for each individual skid needs to be reviewed before each project. The aim is for all OCS offshore skids to be DNV compliant for offshore operations and before each project the status should be reviewed.

OCS has Equipment passports for individual Engines, Skids and Fluid Ends which must be reviewed before each project to assess the status. The equipment passport gives the working history, maintenance and certification history for Engines, Fluid Ends and Pump skids.

It is important to regularly review the list of critical spare parts of the equipment before each project. Common problems occur in these units during the operation include:

- Problem with Drive coupling between Engine and Fluid End.

- Pump impellers and internals.

- Pump Seals and Bearings.

Where failures occur during operations Equipment bulletins will be issued to document the problem and the remediation solutions applied. The equipment bulletin will be circulated to all field engineers to be informed about the possible failure that can occur during the operation and thereby avoid future failure.

This equipment file remains a live document and will be constantly updated by the equipment department.